Описание Проекта

Electric Dry Mix Shotcrete Machine

5 причины выбора нашей продукции

- Dry mix or wet concrete spryaing machine;

- 3 КУБ/Ч,5 КУБ/Ч,9 КУБ/Ч,10-30 КУБ/Ч ;

- Водить машину: Электрический, дизель, пневматический ;

- General or anti-explosion;

- Different wheels;

Горячее напыление бетона (опционально):

- Dry and wet mix shotcrete machine

- Dry mix shotcrete , Мокрая смесь торкрет-бетона

- Concrete Spraying Convey pump

| Модель | OPZ-3 | OPZ-5 | OPZ-9 |

| Выход | 3м3/h | 5.5м3/h | 9м3/h |

| Max.conv.dist | 200 м | 200 м | 150 м |

| Water cement ratio | <0.4 | <0.4 | <0.35 |

| Max.Aggregate.size | 10 мм | 15 мм | 20 мм |

| Внутренний размер шланга | φ42/50 mm | φ50 mm | φ64 mm |

| Рабочее давление воздуха | 0.2-0.6 МПа | 0.2-0.6 МПа | 0.2-0.6 МПа |

| Расход воздуха | 13-14м3/min | 15-16м3/min | 17-18м3/min |

| Motor power | 3 кВт(4hp) | 5.5 кВт(7.5hp) | 7.5 кВт(10hp) |

| Dimension | 1130x1020x540mm | 1350x1020x750mm | 1500x1320x830mm |

| Weight | 520кг | 780кг | 980кг |

| Basic chassis | ①.Tyre ②.Skid ③.Rail-wheel | ||

| Driving Type | Diesel engine drive | ||

Concrete spraying shotcrete machine

Introduction Of Electric Gunite Machine

Gunite, also known as “dry process shotcrete”, uses a different process than wet process shotcrete. Gunite machines use air pressure to convey dry material from the machine through the hose to the nozzle where water is added. OPZ Series Electric Dry-mix Gunite Machine is a low to high production, continuous-feed material placement unit for dry-mix gunite or refractory materials. Shotcrete machine is equally at home underground in a mining environment as it is on a construction jobsite. This kind gunite machine has a rotor feed system, which stands up job-after-job to ensure a long service life with low maintenance. Several hose and nozzle options are available to meet the demands of every gunite / shotcrete spraying application.

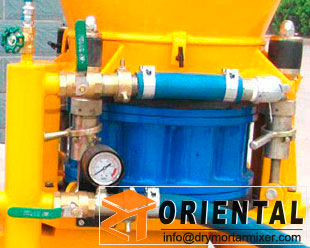

Машины для торкретирования Деталь:

Стальная футеровка для машинного торкретирования,торкрет-бетон под уплотняющую пластину,верхняя уплотнительная пластина из торкрет-бетона,ротор,сверхкамера,коническая втулка,резиновый локоть,шланг для подачи торкретбетона,торкрет-сопло,быстрое соединение,соединение,босс сопла,завихритель,коробки передач,распределитель,шина

Features of Dry Mix Gunite Shotcrete Machine

1:Non-adhesion going through rotor with new material chamber, completely eliminate bonding and blocking during operation so as to reduce clearance and maintenance period;

2:Four-point clamping device make it easy to adjust the press between sealing plate and rotor disk so as to no air and dust leak and prolong consumption parts life;

3:Low pressure and low speed wortex air transport;

4:Well compact and seal, small dust, durable rubber plate;

5:Apply to steel fiber or chemical fiber concrete spraying.

Applications Of Dry Mix Gunite Shotcrete Machine

Dry Mix Gunite Shotcrete Machine can be used thanks to its compact design and mobility where space is at a premium e.g. in mines and galleries. Other potential applications are slope and hillside protection, lining of water tanks and swimming pools, guniting for single and double shell tunnel construction, backfilling of tubing. It is available in the electric, air or diesel.

The power system is consisted by technical diesel engine or electrical engine. It can drive the pumping system directely which samplized the linkage structure and improved the efficiency. Strong power system reduced the rate of occuring faults;

The main hydraulic pump and valve group of hydraulic system is adopted Gemany Rexroth open-style system with accurate and reliable exchanging;

The elements of electrical controlling system is adopted Japan and Gemany’s original parts.The excellent assembly quality fully guaranteed the function of electrical controlling system;

The special design of hopper and vane reduces the space of mixing blind angle thus makes the machine suitable for many kinds of concrete;

The Intelligentize & hommization design,easy to care and operate;

The specific configuration can be changed according to client’s situation.