Machine à jointoyer les portes de sécurité

1. S'adapter au transport des matériaux de coulis: poudre de mastic, peinture, peinture au latex, vraie peinture pour pierre, mortier de ciment, mortier sec, mortier d'isolation thermique, matériau imperméable, matériau ignifuge, matériau d'isolation thermique, matériau insonorisant et autres matériaux solubles dans l'eau.

2. Ajustez la taille du débit pour augmenter l'effet.

3. The electric control box can be switched.

4. The connection of the feeding tube can be rotated for easy operation.

5. High construction efficiency and good quality.

6. Small size, easy to carry on site, and low cost of accessories, simple maintenance.

7. Easy to use, fast, save materials, save labor, and save money.

8. Material ratio (ciment) 0.7:3 mortier

Product use:

Suitable for cement grouting during security door installation, caulking of door frame and aluminum alloy bed frame, caulking, jointing and reinforcement of large hydraulic engineering, filling epoxy resin glue, bolt grouting, etc.. Cracks caused by earthquakes, etc., are professional caulking tools for door and window installation projects.

Caractéristiques:

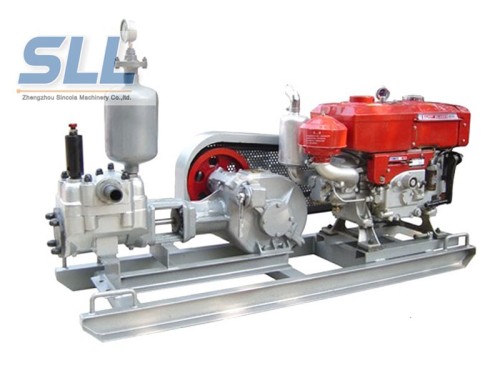

1. Compact and simple structure, excellent performance and reasonable price.

2, the use of single-phase 220V power supply, small size, easy to move, easy to operate and maintain.

3, can be poured under 3mm of various construction mortar, with special joints, can be continuously grouted.

4. Passive boost. When the slurry is filled, the pressure is gradually increased to facilitate control and maintain the grouting pressure.

5, can be used for surface layer spraying operations (requires spray gun and air compressor)

Indice de sécurité de fonctionnement des machines à béton projeté à sec

1. Lors de la connexion du câble d'alimentation, relier la résistance à la traction, le joint d'interface du câble, et la protection de la surface antidéflagrante.

2. Lorsque la machine à béton projeté pulvérise les matériaux, it is necessary to prevent long and large metal blocks such as bolts and nuts from entering the material chamber to avoid accidents caused by the machine.

3. When the dry shotcrete machine operation is carried out, the main engine operator should observe the pressure of the gas pressure gauge at any time. If the air pressure is abnormally high, the feeding should be stopped. After the working state of the gas circuit is normal, it will enter normal operation.

4. The components and important components and raw materials in the shotcrete machine are all selected to meet the requirements of the standard. The user shall not replace it at will. If it is necessary to replace it, the components or raw materials that meet the relevant standards shall be selected.