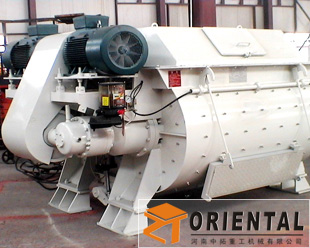

Twin Shaft Forced Concrete Mixer

JS Concrete mixer Applicable to all types of precast plant and water, roads, bridges and other industrial and civil engineering construction sector mixing dry hard concrete, fluidity concrete, lightweight aggregate concrete and all kinds of mortar. Concrete mixer primarily as a supporting medium-sized mixing station hosts.

![]()

|

Model

|

JS500

|

JS750

|

JS1000

|

JS1500

|

JS2000

|

JS3000

|

|

Charging Volume (L)

|

800

|

1200

|

1600

|

2400

|

3200

|

4800

|

|

Discharging Volume (L)

|

500

|

750

|

1000

|

1500

|

2000

|

3000

|

|

Theoretic Productivity (m3/h)

|

25

|

35

|

50

|

75

|

100

|

130

|

|

Max. Aggregate Size (mm)

|

60~80

|

60~80

|

60~80

|

60~80

|

60~80

|

80~100

|

|

Power (KW)

|

27.5

|

40.45

|

59.1

|

68

|

101

|

2×55

|

|

Outline dimension (L×W×H )(mm)

|

3030×

2300 ×2680 |

4150×

2250 ×2280 |

5250×

2250 ×2350 |

5650×

2250 ×2510 |

5860x

2250 x2735 |

4050x

2680 x2150 |

|

Total Weight (KG)

|

4000

|

5700

|

8000

|

9500

|

10000

|

11500

|

|

Discharging Height(mm)

|

1500/3800

|

2000/3800

|

3900

|

3900

|

3900

|

3900

|

Application Of Twin shaft concrete mixer

JS Concrete mixer Applicable to all types of precast plant and water, roads, bridges and other industrial and civil engineering construction sector mixing dry hard concrete, fluidity concrete, lightweight aggregate concrete and all kinds of mortar. Concrete mixer primarily as a supporting medium-sized mixing station hosts.

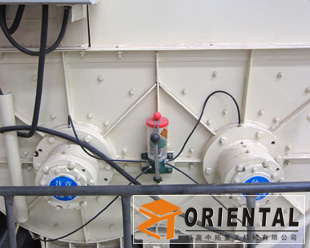

The JS Concrete mixer design of advanced, compact structure, high reliability. Linings, mixing blades are high hardness, high toughness wear-resistant alloy steel, long service life. Discharge system uses hydraulic station centralized control, fast and reliable. Centralized lubrication system with electric pump oil lubrication. Electrical control system main parts adopt imported components, excellent performance and high reliability.

Characteristic Of Twin Shaft Forced Concrete Mixer

Diesel Engine Power Hydraulic Concrete Mixer is specially designed for some remote areas without electricity to achieve mechanized construction. The principle is the existing JS concrete mixer is installed a diesel power generation system, and this system can supply electricity power to make sure the normal running of mixer. The generating system’s out power is 15KW, so it can also supply extra part of electricity power to other small devices, as concrete vibrators and lighting equipments, while it’s keeping the mixer’s operation.In addition, the machine can also match the external power directly, achieves diesel-electric dual-use.

Features of JS Concrete Mixer

Adding a water pump for water circulation between water tank and water radiator,it keeps the water temperatures stable Removing the air sucking point from the back to the front to reduce its sucking dust ,it will be helpful to prolong the service life of the engine.

JS Concrete Mixer is a bipyramid reversal discharging self-loading mixer concrete, the mixing drum’s forward rotation is mixing, reverse rotation is discharging. The mixer for concrete has the benefits of simple structure, reliable, good mixing quality, high efficiency, light weight, and easy manipulation of maintenance, so it is more advanced models of cement concrete mixer. Because outfitting with a diesel-powered engine, it is more applicable to the remote areas and the wild which have no electric power supply.